We are dedicated to ensuring that all of our clients - new, old, and prospective - have the latest information available about our analytical services capability, and how its progressive development over the last 40 years will benefit your business both now and in the future.

Ever-increasing sample diversity and complexity, and rapid growth in our customer numbers, combined with a need to turn around sample results at a faster rate have resulted in significant investment in our laboratory facilities.

David Crouch, Senior Planner/Scheduler at Babcock, who frequently utilises Terra Analytical's services and expertise for equipment servicing says:

"Prevention of delays in airport operations is crucial to the business and having Terra Analytical’s fluid analysis programme in place has proven valuable on many occasions.

The prompt processing and reporting of fluids has allowed Babcock to monitor existing and emerging machine driveline failures to plan and schedule corrective maintenance actions prior to failure, subsequently avoiding unplanned machine downtime for our customer.

The Cat SOS dashboard works well to provide live data on all historic reports and active fluid samples which is a great resource when auditing and reviewing machine health history, and the clear asset health icons and dashboard charts provide a very quick and clear indicator.

Thank you, Terra Analytical, for working with Babcock to help us provide a great service to our customers, we look forward to building our fleet fluid analysis database with you."

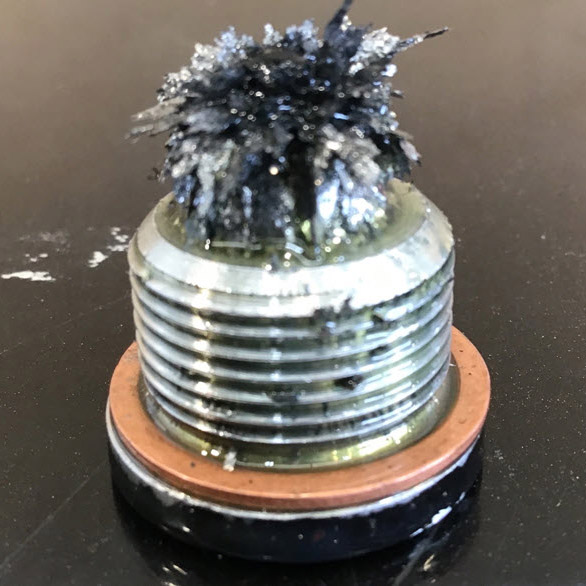

Below are some of the findings that Terra Analytical's services have uncovered, preventing costly failure and downtime. The plug debris is due to a differential drive shaft and housing failure which prompted the entire fleet to be monitored closely.

Similarly, Geoff Eban, Project Manager at Coastguard Nelson, shared this update with us following some testing the Terra Analytical lab carried out:

"We established that the oil contamination was from the aftercooler, allowing salt water to enter the inlet manifold.

It resulted in the engine being scrapped and a new one fitted. This of course was a major set back for us – the rescue vessel was out of service for 2 ½ months.

However, the oil analysis saved us from an engine failure during an emergency. And your initiative to go ahead and check for chlorine proved to be invaluable to the troubleshooting process.

Thank you."